Brussels Parliamentary Breakfast and Open EASN Workshop

On February 16th 2016, EASN will be holding in Brussels a dual event, dedicated on Aeronautics Academia. A Parliamentary Breakfast, hosted by MEP Dieter-Lebrecht KOCH, co-chair of the Committee of Transport and Tourism, and an Open EASN Workshop. The Parliamentary Breakfast on “Taking off to the future of European Aviation, is academia still on board?” will address topics such as: Academic research for seamless and affordable air transport in Europe; Intermodality as innovation driver; and How to achieve an integrated European aviation education system.

On February 16th 2016, EASN will be holding in Brussels a dual event, dedicated on Aeronautics Academia. A Parliamentary Breakfast, hosted by MEP Dieter-Lebrecht KOCH, co-chair of the Committee of Transport and Tourism, and an Open EASN Workshop. The Parliamentary Breakfast on “Taking off to the future of European Aviation, is academia still on board?” will address topics such as: Academic research for seamless and affordable air transport in Europe; Intermodality as innovation driver; and How to achieve an integrated European aviation education system.

The Parliamentary breakfast will be followed by the Open EASN Workshop on “Aeronautical academic research in the light of the new realities of the 21st century; are we actually performing the research we need?”. This EASN Open Workshop will serve as a platform for representatives of the European Academia, Industry, Research Centers and the EC to present

their viewpoints. It will foster an open discussion, aiming at reaching some common measures for maintaining innovation on the European Aviation development chain.

EASN Members are invited to attend both events but due to the limited seats available in both events, pre-registration and confirmation is required, interested parties can find out more and register here.

Interview of Professor Joachim Szodruch, Chairman of the Board of Hamburg Aviation

Professor Joachim Szodruch, Chairman of the Board of Hamburg Aviation, evaluates the efforts made in the frame of FP7 to reach the targets set by the Vision 2020, comments on the realization of Horizon 2020 in Aeronautics-related upstream research, discusses the role of Academia in the new context, and many more.

Professor Joachim Szodruch, Chairman of the Board of Hamburg Aviation, evaluates the efforts made in the frame of FP7 to reach the targets set by the Vision 2020, comments on the realization of Horizon 2020 in Aeronautics-related upstream research, discusses the role of Academia in the new context, and many more.

Read the full interview on the EASN website.

6th EASN International Conference on Innovation in European Aeronautics Research, October 18 - 21, 2016, Porto, Portugal

In 2016, for the first time, the European Aeronautics Science Network will convene In Portugal. The 6th International Conference of EASN will be co-organised with the Institute of Science and Innovation in Mechanical and Industrial Engineering (INEGI) of the University of Porto (FEUP). The 6th EASN International Conference is set to be the larger, broader and most comprehensive gathering of the association. It will include Plenary Sessions by renowned speakers and Open Discussions with distinguished researchers from the industry and academia. Thematic Sessions housing the 90% of current European aeronautics research programs and Technical Workshops. The annual EASN Conference provides an opportunity for participants to share their recent activities and point of view regarding specific research fields in Aeronautics and Air Transport and is the ideal place to meet and exchange ideas with eminent researchers from the industry and academia.

In 2016, for the first time, the European Aeronautics Science Network will convene In Portugal. The 6th International Conference of EASN will be co-organised with the Institute of Science and Innovation in Mechanical and Industrial Engineering (INEGI) of the University of Porto (FEUP). The 6th EASN International Conference is set to be the larger, broader and most comprehensive gathering of the association. It will include Plenary Sessions by renowned speakers and Open Discussions with distinguished researchers from the industry and academia. Thematic Sessions housing the 90% of current European aeronautics research programs and Technical Workshops. The annual EASN Conference provides an opportunity for participants to share their recent activities and point of view regarding specific research fields in Aeronautics and Air Transport and is the ideal place to meet and exchange ideas with eminent researchers from the industry and academia.

During the three days of the Conference, the General Assembly of the EASN association will be held. The General Assembly will discuss the achievements of the current Board of Directors and will set the frame and provide guidelines for the future activities of the association. At the end of the General Assembly, all effective members will be called to cast their vote and elect the new BoD that will lead the association for the next 3 years. All EASN members are invited to join the General Assembly.

More information about the Conference will be posted on a regular basis on the EASN website as well as on the 6th EASN International Conference minisite.

New EASN representatives in ACARE

Having completed a term of more than 3 years and in view of the SRIA update which officially kicked of a few days ago, EASN has renewed its nominated representatives in the ACARE Working Groups. The EASN representatives closely follow the activity of the groups, contribute with their viewpoint and inform the EASN community about any topics of interest to the European Academia.

Having completed a term of more than 3 years and in view of the SRIA update which officially kicked of a few days ago, EASN has renewed its nominated representatives in the ACARE Working Groups. The EASN representatives closely follow the activity of the groups, contribute with their viewpoint and inform the EASN community about any topics of interest to the European Academia.

The new EASN representatives in ACARE can be found on the EASN website.

EASN at Aerodays2015

The EASN Association was present at the 7th European Aeronautics Days, held on 20-23 October 2015 at the QEII Centre in Central London, UK. This unique conference, attended by more than 1000 delegates, 280 key speakers and 90 exhibitors, has acted as a positive enabler for industry, governments, the European Commission, research institutions, academia and many others, to come together, interact and present strategic perspectives and achievements in aviation research and innovation. The three days conference included technical sessions, research and technology showcases and hosted keynote addresses from Aviation CEOs, European Commissioners, UK Ministers and heads of key Agencies.

The EASN Association was present at the 7th European Aeronautics Days, held on 20-23 October 2015 at the QEII Centre in Central London, UK. This unique conference, attended by more than 1000 delegates, 280 key speakers and 90 exhibitors, has acted as a positive enabler for industry, governments, the European Commission, research institutions, academia and many others, to come together, interact and present strategic perspectives and achievements in aviation research and innovation. The three days conference included technical sessions, research and technology showcases and hosted keynote addresses from Aviation CEOs, European Commissioners, UK Ministers and heads of key Agencies.

The EASN Association was represented through several “channels” during AERODAYS 2015:

- EASN hosted its own dedicated booth, where members of the BoD were present and available for short B2B meetings. Moreover, posters and leaflets were available for distribution at the booth presenting to the public information related to EASN involved projects.

- EASN took part in the parallel session 1H on the first day of the event with the presentation of Prof. Zdobyslaw Goraj on “European Aeronautics Universities – Hatchery of New Knowledge and Breakthrough Technologies”. The presentation is available for viewing and downloading here.

Interview of Mr. Piet-Christof Woelcken, Project Coordinator of the SARISTU project

Mr. Piet-Christof Woelcken (Airbus Operations GmbH), Project Coordinator of the SARISTU project, shares his experience on managing the most successful Level-2 project in Aviation funded under FP7.

Mr. Piet-Christof Woelcken (Airbus Operations GmbH), Project Coordinator of the SARISTU project, shares his experience on managing the most successful Level-2 project in Aviation funded under FP7.

Read the full interview on the EASN website.

5th EASN Association International Workshop on Aerostructures

The European Aeronautics Science Network has successfully carried out the 5th, out of a series of annual specialized Workshops, in the field of Aerostructures. The workshop was hosted by the University of Manchester, on 2-4 September 2015. The EASN International Workshops, every year, aim to share high quality, current achievements and new upstream ideas for future research and in the same time to offer their participants a forum to meet and present among relative audience, their latest advancements.

The European Aeronautics Science Network has successfully carried out the 5th, out of a series of annual specialized Workshops, in the field of Aerostructures. The workshop was hosted by the University of Manchester, on 2-4 September 2015. The EASN International Workshops, every year, aim to share high quality, current achievements and new upstream ideas for future research and in the same time to offer their participants a forum to meet and present among relative audience, their latest advancements.

In this frame, the event proved to be a unique opportunity for the participants to obtain an overview of the recent advancements in the research scene, with presentations from 21 ongoing research projects and support actions which were performed in three parallel sessions. In addition, 30 scientific papers have been published in the Workshop proceedings, some of which will be published following peer review in two scientific journals, namely the "International Journal of Structural Integrity" (IJSI) of Emerald Group Publishing and “Advances in Aircraft and Spacecraft Science” (AAS) of Techno-Press.

Furthermore, distinguished speakers updated the delegates about the future Industrial trends and European priorities with respect to the medium and long-term goals, as set by the aviation stakeholders and participants had the opportunity to engage into fruitful discussions and networking with more than 100 representatives of the Academia, research community and industry.

Finally and responding to the increasing interest from the European Aeronautics Community for a scientific event which offers a forum for discussion and exchange of information about state-of-the-art research and development activities in Aeronautics and Air Transport, EASN has announced its 6th annual International Conference on Innovation in European Aeronautics Research which will be held on October 18 – 21, 2016 at the INEGI premises, Porto, Portugal. More information on the outcome of the workshop, including the performed presentations, is available here.

The IASS project, aiming at developing a new generation of composites able to overcome some of the current limitations of aeronautic materials, was completed in August 2015. The traditional approach to the development of structural aeronautic materials is to address the load-carrying and other functional requirements separately, resulting in suboptimal load-bearing materials with the penalty of added weight. The IASS project achieved in developing self-healing, load-bearing materials and structures with all functionalities integrated in a single material able to meet many important requirements of structural materials for primary structures in aeronautics. The main concept underpinning the project was the use of the nanotechnology strategy for the production of new, high performance structural multifunctional materials. Using all the results of the IASS consortium, promising multifunctional resins able to increase flame resistance, electrical conductivity and regenerative ability have been developed. Multifunctional carbon fiber reinforced panels (CFRPs) have been manufactured using the multifunctional resin. CFRPs have been manufactured by Resin Film Infusion using a non-usual technique to infuse a nano-filled resin into the carbon fiber dry preform. Several flat panels have been produced and tested with respect to all the integrated functionalities. The electrical conductivity was found to be about 2x104S/m in the direction parallel to the fibers, whereas a value between 3.0 and 4.0 S/m was found in the directional orthogonal to the fibers. These values are among the highest values reached until now for nanofilled resins impregnating carbon fibers. The panels also demonstrated enhanced flame resistance properties. Furthermore, due to the autorepair ability, a significant decrease in the fatigue crack growth rate by approximately 80 % was achieved.

The IASS project, aiming at developing a new generation of composites able to overcome some of the current limitations of aeronautic materials, was completed in August 2015. The traditional approach to the development of structural aeronautic materials is to address the load-carrying and other functional requirements separately, resulting in suboptimal load-bearing materials with the penalty of added weight. The IASS project achieved in developing self-healing, load-bearing materials and structures with all functionalities integrated in a single material able to meet many important requirements of structural materials for primary structures in aeronautics. The main concept underpinning the project was the use of the nanotechnology strategy for the production of new, high performance structural multifunctional materials. Using all the results of the IASS consortium, promising multifunctional resins able to increase flame resistance, electrical conductivity and regenerative ability have been developed. Multifunctional carbon fiber reinforced panels (CFRPs) have been manufactured using the multifunctional resin. CFRPs have been manufactured by Resin Film Infusion using a non-usual technique to infuse a nano-filled resin into the carbon fiber dry preform. Several flat panels have been produced and tested with respect to all the integrated functionalities. The electrical conductivity was found to be about 2x104S/m in the direction parallel to the fibers, whereas a value between 3.0 and 4.0 S/m was found in the directional orthogonal to the fibers. These values are among the highest values reached until now for nanofilled resins impregnating carbon fibers. The panels also demonstrated enhanced flame resistance properties. Furthermore, due to the autorepair ability, a significant decrease in the fatigue crack growth rate by approximately 80 % was achieved.

The CORSAIR New Industrial Portable Cold Spray Unit was successfully developed and repairs are now being realized on various aircraft components provided by the industrial partners of the consortium. The first materials that will be tested are the Al alloys of interest for the industrial partners. The results will be compared with the repairs obtained by traditional fixed Cold Spray units for assessing opportunities and limits of this new plant for the in-situ repairs. A new Cold Spray nozzle design approach has been developed, which takes into account the proper gas expansion through the divergent part of the nozzle, as well as the maximum acceleration achieved by the particles. Short length (53 mm) and low gas consumption nozzles were designed for specific aeronautical applications. In particular, short nozzles were designed for mobile unit applications, allowing longer spraying operation times and reduced operation costs. The prediction of interfacial crack growth of cold sprayed coatings is an important part of lifetime assessment of the coatings. Currently, there are no such models available for cold sprayed coatings and hence, delamination of coating is described by cohesive law implemented in Finite Element (FE) software. Two cohesive material parameters (strength and energy) are required in both normal and tangential direction to the interface, in order to create the FE damage model. The specimens needed to get the value of the damage parameters are currently in the stage of manufacturing.

The CORSAIR New Industrial Portable Cold Spray Unit was successfully developed and repairs are now being realized on various aircraft components provided by the industrial partners of the consortium. The first materials that will be tested are the Al alloys of interest for the industrial partners. The results will be compared with the repairs obtained by traditional fixed Cold Spray units for assessing opportunities and limits of this new plant for the in-situ repairs. A new Cold Spray nozzle design approach has been developed, which takes into account the proper gas expansion through the divergent part of the nozzle, as well as the maximum acceleration achieved by the particles. Short length (53 mm) and low gas consumption nozzles were designed for specific aeronautical applications. In particular, short nozzles were designed for mobile unit applications, allowing longer spraying operation times and reduced operation costs. The prediction of interfacial crack growth of cold sprayed coatings is an important part of lifetime assessment of the coatings. Currently, there are no such models available for cold sprayed coatings and hence, delamination of coating is described by cohesive law implemented in Finite Element (FE) software. Two cohesive material parameters (strength and energy) are required in both normal and tangential direction to the interface, in order to create the FE damage model. The specimens needed to get the value of the damage parameters are currently in the stage of manufacturing.

The i-VISION project is glad to announce its strong participation in the 7th European Aeronautics Days that was held on 20-23 October 2015 at the QEII Centre in London, UK. i-VISION was present at this event by hosting a dedicated booth where project related posters were displayed and leaflets were available for distribution. In addition, a demo application of a virtual reality cockpit created within the project was exhibited enabling the participants to actually “explore” the “i-VISION experience”. This demo contains a first version of the Semantic Engine, the semantic scene graph interface and mappings and workflows as Linked Programmes and it is expected to be used as a reusable and low-cost simulation test-bed for experimenting with various configurations and set-ups of virtual cockpits so as to allow the human-centred assessment of future cockpit architectures. Finally, a brief i-VISION

The i-VISION project is glad to announce its strong participation in the 7th European Aeronautics Days that was held on 20-23 October 2015 at the QEII Centre in London, UK. i-VISION was present at this event by hosting a dedicated booth where project related posters were displayed and leaflets were available for distribution. In addition, a demo application of a virtual reality cockpit created within the project was exhibited enabling the participants to actually “explore” the “i-VISION experience”. This demo contains a first version of the Semantic Engine, the semantic scene graph interface and mappings and workflows as Linked Programmes and it is expected to be used as a reusable and low-cost simulation test-bed for experimenting with various configurations and set-ups of virtual cockpits so as to allow the human-centred assessment of future cockpit architectures. Finally, a brief i-VISION

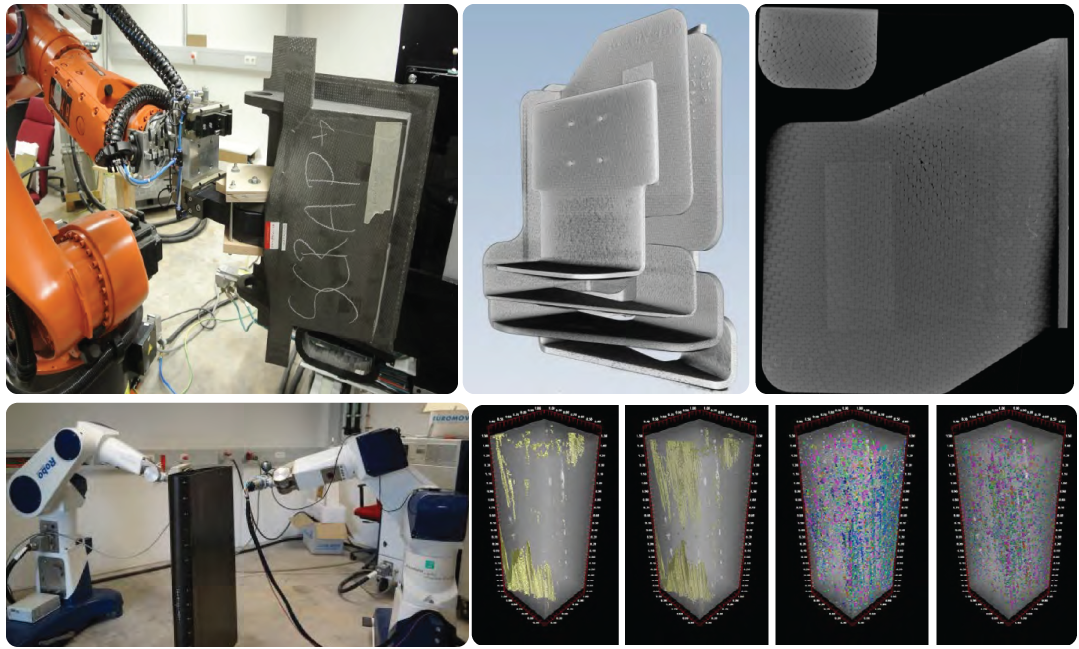

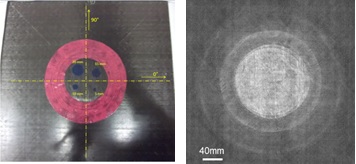

QUICOM linked the activities of 12 partners from 6 European countries in order to establish a strong team with expertise in X-ray techniques, software, application, and CFRP materials to collaborate on reliable, fully 3D inspections of aeronautic components. The progress beyond the state of the art focused on the extensive use of X-ray computed tomography (XCT) techniques to detect defects in small high volume, hybrid and large composite structures. Advanced X-ray methods in different modalities were developed and applied for NDT of composite components. The developed QUICOM technology platform assures thorough inspections of the structure at high levels of detail, and hence allows for reducing the design, production and rework costs due to an enhanced understanding of the real inner 3D structures. The availability of such an inspection enables higher structural efficiency and higher performance than recent state-of-the-art with the same or higher level of safety. Understanding and knowledge of the damage in a composite structure is key factors for the application of a damage tolerance approach. The computer models, developed and optimized within QUICOM, allow generating a detailed understanding on the effect of production flaws, on the deviation in yarn geometry or shape, as well as on the mechanical properties of the composite parts. Therefore, a potential increase in the amount of rework and a decrease of production costs is expected, assuring damage tolerance. The QUICOM project was running from 10/2012 to 09/2015 in a total project lifetime of 36 months.

QUICOM linked the activities of 12 partners from 6 European countries in order to establish a strong team with expertise in X-ray techniques, software, application, and CFRP materials to collaborate on reliable, fully 3D inspections of aeronautic components. The progress beyond the state of the art focused on the extensive use of X-ray computed tomography (XCT) techniques to detect defects in small high volume, hybrid and large composite structures. Advanced X-ray methods in different modalities were developed and applied for NDT of composite components. The developed QUICOM technology platform assures thorough inspections of the structure at high levels of detail, and hence allows for reducing the design, production and rework costs due to an enhanced understanding of the real inner 3D structures. The availability of such an inspection enables higher structural efficiency and higher performance than recent state-of-the-art with the same or higher level of safety. Understanding and knowledge of the damage in a composite structure is key factors for the application of a damage tolerance approach. The computer models, developed and optimized within QUICOM, allow generating a detailed understanding on the effect of production flaws, on the deviation in yarn geometry or shape, as well as on the mechanical properties of the composite parts. Therefore, a potential increase in the amount of rework and a decrease of production costs is expected, assuring damage tolerance. The QUICOM project was running from 10/2012 to 09/2015 in a total project lifetime of 36 months.

Having completed two full years of operation, the FP7 Coordination and Support Action

Having completed two full years of operation, the FP7 Coordination and Support Action

CATER experts consultation survey re-launched!

CATER experts consultation survey re-launched!

SUNJET II, an initiative aiming at establishing a sustainable network for Japan-Europe aerospace research and technology cooperation, was present at the “7th European Aeronautics Days” held on 20-23 October 2015 in London, UK. SUNJET II hosted its own stand where representatives from both the EU and the Japanese delegation were present and available for short B2B meetings to discuss about the possibilities for cooperation and how one can be part of this initiative. Additionally, SUNJET II was represented in parallel session 3H of the second day “International Cooperation in Aeronautics Research”.

SUNJET II, an initiative aiming at establishing a sustainable network for Japan-Europe aerospace research and technology cooperation, was present at the “7th European Aeronautics Days” held on 20-23 October 2015 in London, UK. SUNJET II hosted its own stand where representatives from both the EU and the Japanese delegation were present and available for short B2B meetings to discuss about the possibilities for cooperation and how one can be part of this initiative. Additionally, SUNJET II was represented in parallel session 3H of the second day “International Cooperation in Aeronautics Research”.

The SARISTU project aiming at reducing manufacturing and operational cost of civil airliners was successfully completed in time in August 2015. Organized along the major principal components of an aircraft, development and integration activities centered on wing specific applications on one hand and fuselage applications on the other. With respect to the wing specific applications, the further maturation and development of conformal morphing technologies, which enable a smooth shape change of aerodynamic surfaces, as well as the integration of structural health monitoring were at the focus of activities. By enabling the consideration of conformal moving surfaces at the aircraft design stage, SARISTU verified these technologies capabilities to reduce the fuel consumption of future airliners by 6,5% while at the same time offering improvements in flight path noise of up to 8dB. Fuselage specific applications centered on the integration of structural health monitoring technologies in the aircraft architecture as well as the further maturation of multifunctional structures and the improvement of a typical fuselage’s robustness. By enabling a significantly more rapid damage localization and assessment than is currently possible, aircraft structural inspections due to accidental damages can be performed much quicker. This in turn was shown to result in a cost reduction of such in-service inspection activities of more than 1,33% for carbon fibre based fuselage structures. Furthermore, improvements were investigated and developed within SARISTU’s multifunctional structures approach which, among other solutions, arose from integrating carbon nanotubes into the basic skin-stringer-frame system. The resulting gains can be exploited both directly and indirectly to realize weight savings of 5%. Culminating in wing and fuselage specific demonstration and performance verification activities in its fourth and final year, SARISTU has shown benefits beyond its original scope of more affordable air travel.

The SARISTU project aiming at reducing manufacturing and operational cost of civil airliners was successfully completed in time in August 2015. Organized along the major principal components of an aircraft, development and integration activities centered on wing specific applications on one hand and fuselage applications on the other. With respect to the wing specific applications, the further maturation and development of conformal morphing technologies, which enable a smooth shape change of aerodynamic surfaces, as well as the integration of structural health monitoring were at the focus of activities. By enabling the consideration of conformal moving surfaces at the aircraft design stage, SARISTU verified these technologies capabilities to reduce the fuel consumption of future airliners by 6,5% while at the same time offering improvements in flight path noise of up to 8dB. Fuselage specific applications centered on the integration of structural health monitoring technologies in the aircraft architecture as well as the further maturation of multifunctional structures and the improvement of a typical fuselage’s robustness. By enabling a significantly more rapid damage localization and assessment than is currently possible, aircraft structural inspections due to accidental damages can be performed much quicker. This in turn was shown to result in a cost reduction of such in-service inspection activities of more than 1,33% for carbon fibre based fuselage structures. Furthermore, improvements were investigated and developed within SARISTU’s multifunctional structures approach which, among other solutions, arose from integrating carbon nanotubes into the basic skin-stringer-frame system. The resulting gains can be exploited both directly and indirectly to realize weight savings of 5%. Culminating in wing and fuselage specific demonstration and performance verification activities in its fourth and final year, SARISTU has shown benefits beyond its original scope of more affordable air travel.

The UMRIDA project aims at a paradigm shift in virtual prototyping away from deterministic design towards design under uncertainties, hereby bridging the gap from basic research to industrial design practice. The UMRIDA project focused within the first two years mainly on three large topics: first, the development of methods for handling large number of uncertainties, second, approaches to reduce the dimensionality of the non-deterministic problem including sensitivity analyses and building of surrogate models and third, the integration of these methods into industry ready tools. A variety of different techniques (e.g. Sparse Polynomial Chaos Analysis, Multi-level Monte Carlo simulations (MLMC), Cumulative Distribution Function (CDF), Stochastic Collocation (SC), etc.) is examined and applied by the industrial and research partners.. The developed methods are tested against the novel and unique UMRIDA database with test cases including prescribed uncertainties. Entering the third year of the project, the UQ tool developed by NUMECA for simultaneous operational and geometrical uncertainties, based on its FINETM/Design software package is released in an official version. Furthermore, the development of generalized geometrical uncertainties is introduced, manufacturing uncertainties are accounted for.. The consortium will focus within the last year of the UMRIDA project on Robust Design Optimization. A Robust Design workshop will be organized in Brussels on September 20th and 21st 2016.

The UMRIDA project aims at a paradigm shift in virtual prototyping away from deterministic design towards design under uncertainties, hereby bridging the gap from basic research to industrial design practice. The UMRIDA project focused within the first two years mainly on three large topics: first, the development of methods for handling large number of uncertainties, second, approaches to reduce the dimensionality of the non-deterministic problem including sensitivity analyses and building of surrogate models and third, the integration of these methods into industry ready tools. A variety of different techniques (e.g. Sparse Polynomial Chaos Analysis, Multi-level Monte Carlo simulations (MLMC), Cumulative Distribution Function (CDF), Stochastic Collocation (SC), etc.) is examined and applied by the industrial and research partners.. The developed methods are tested against the novel and unique UMRIDA database with test cases including prescribed uncertainties. Entering the third year of the project, the UQ tool developed by NUMECA for simultaneous operational and geometrical uncertainties, based on its FINETM/Design software package is released in an official version. Furthermore, the development of generalized geometrical uncertainties is introduced, manufacturing uncertainties are accounted for.. The consortium will focus within the last year of the UMRIDA project on Robust Design Optimization. A Robust Design workshop will be organized in Brussels on September 20th and 21st 2016.

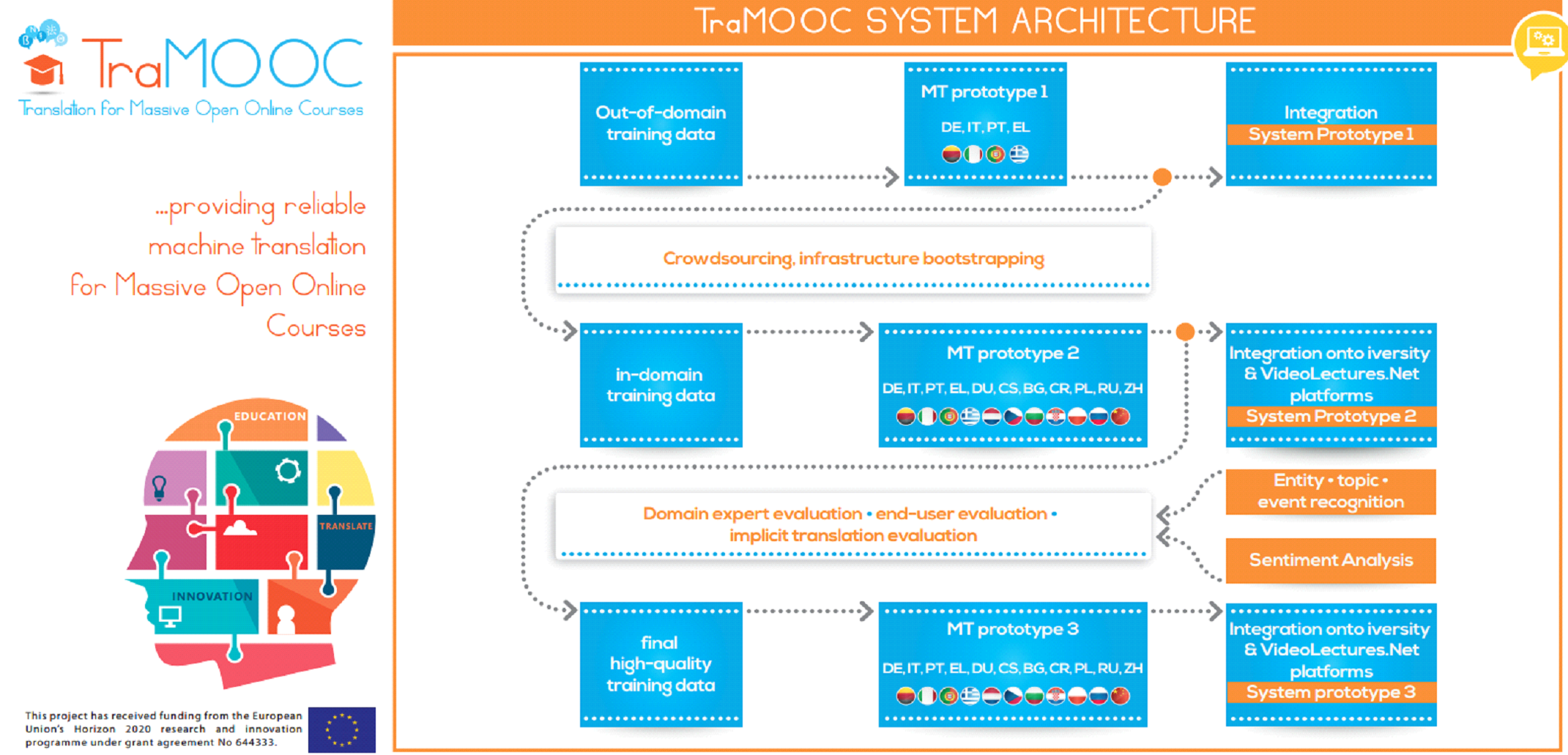

The TraMOOC project is in its 10th month of activities and the partners, after having developed the first Machine Translation (MT) prototype, are going full steam ahead its integration into the Iversity platform. More specifically, during this period the responsibilities of each partner and the language resources and tools to be employed/adapted/developed in TraMOOC have been defined and agreed providing a timeline for the project activities. The timeline is organised around the machine translation prototypes which will be produced within the project, thus making sure that the language resources and tools needed for each prototype will be ready on time. Additionally, a focused survey on existing and readily-available MT infrastructure, which could be employed within TraMOOC for the 11 languages targeted, has been performed. This includes statistical machine translation systems, parallel and monolingual corpora (both in- and out-of-domain), and language tools, the employment of which could be beneficial for the machine translation quality. Finally, during this period the first MT prototype has been developed which provides four of the final eleven language pairs and will be used to perform initial implicit and explicit evaluations for estimating the accuracy of the translated text. It is worth highlighting that the first MT prototype will be succeeded by the second version of the TraMOOC translation prototype in June 2016.

The TraMOOC project is in its 10th month of activities and the partners, after having developed the first Machine Translation (MT) prototype, are going full steam ahead its integration into the Iversity platform. More specifically, during this period the responsibilities of each partner and the language resources and tools to be employed/adapted/developed in TraMOOC have been defined and agreed providing a timeline for the project activities. The timeline is organised around the machine translation prototypes which will be produced within the project, thus making sure that the language resources and tools needed for each prototype will be ready on time. Additionally, a focused survey on existing and readily-available MT infrastructure, which could be employed within TraMOOC for the 11 languages targeted, has been performed. This includes statistical machine translation systems, parallel and monolingual corpora (both in- and out-of-domain), and language tools, the employment of which could be beneficial for the machine translation quality. Finally, during this period the first MT prototype has been developed which provides four of the final eleven language pairs and will be used to perform initial implicit and explicit evaluations for estimating the accuracy of the translated text. It is worth highlighting that the first MT prototype will be succeeded by the second version of the TraMOOC translation prototype in June 2016.

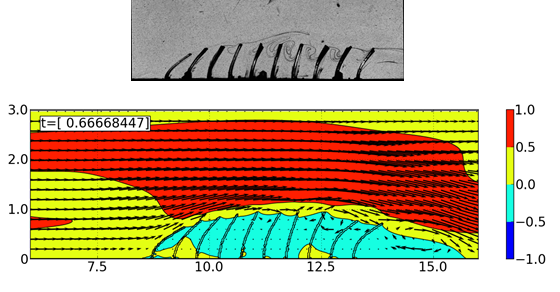

PEL-SKIN: A novel kind of surface coatings in aeronautics. Comparison of experimental and numerical prediction of fluid-structure interaction on walls covered with flexible flaps shows good agreement. Manipulation of bluff body wake and airfoil performance when using attached flaps or filaments has been proven for a range of Reynolds-numbers. Homogenization approach for poro-elastic layer shows possible route for simulations of larger surfaces.

PEL-SKIN: A novel kind of surface coatings in aeronautics. Comparison of experimental and numerical prediction of fluid-structure interaction on walls covered with flexible flaps shows good agreement. Manipulation of bluff body wake and airfoil performance when using attached flaps or filaments has been proven for a range of Reynolds-numbers. Homogenization approach for poro-elastic layer shows possible route for simulations of larger surfaces.

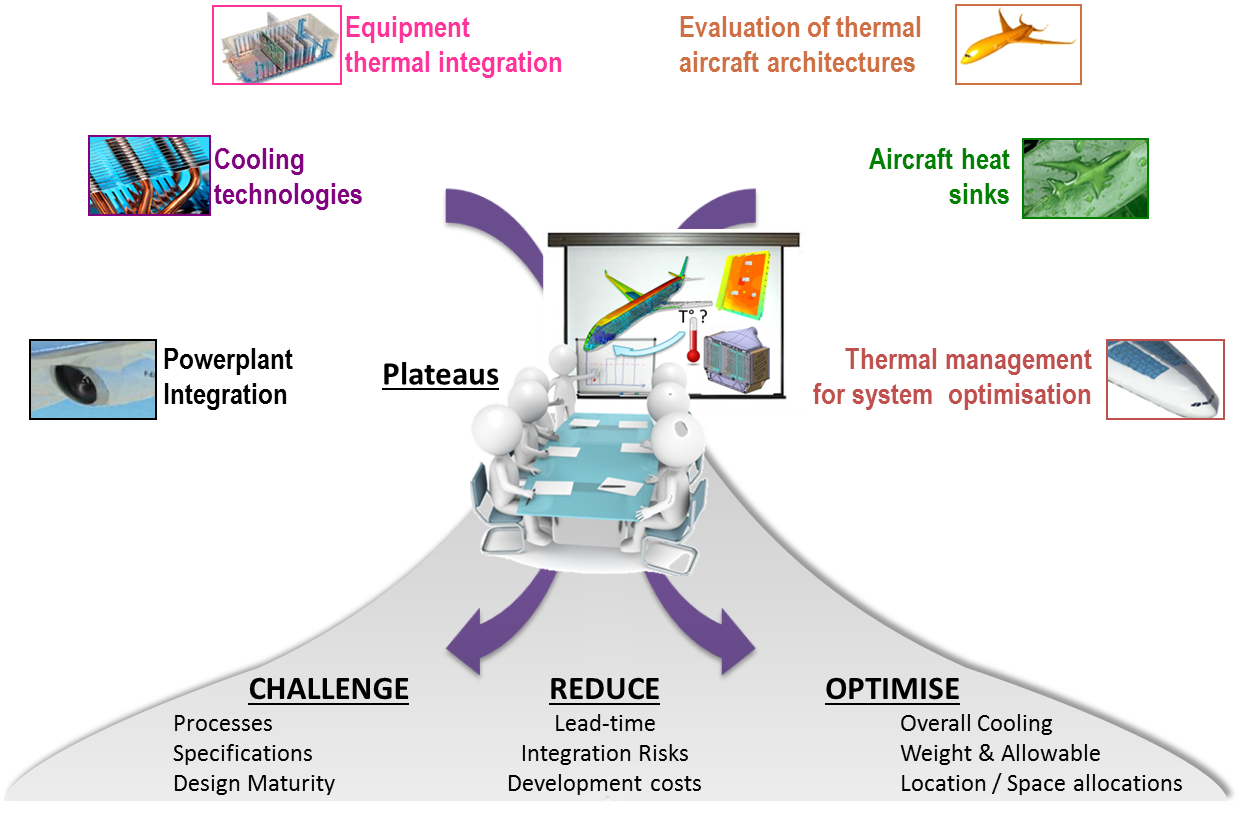

The TOICA project (32 partners) contributes to deliver thermally optimised architectures by developing new trade-off mechanisms, new pyramids of models enabling earlier and more reliable assessments, new methods for more robust and deeper integration of functions, and finally, new capabilities enabling architects to explore more agilely the design space.

The TOICA project (32 partners) contributes to deliver thermally optimised architectures by developing new trade-off mechanisms, new pyramids of models enabling earlier and more reliable assessments, new methods for more robust and deeper integration of functions, and finally, new capabilities enabling architects to explore more agilely the design space.

The JediAce project is reaching the home straight with the help of an international consortium consisting of European and Japanese partners. Aim of the project was to develop new concepts for integrated wing ice protection systems (WIPS). New components shall significantly improve aircraft safety and reduce energy consumption compared to today´s systems. Please visit our website

The JediAce project is reaching the home straight with the help of an international consortium consisting of European and Japanese partners. Aim of the project was to develop new concepts for integrated wing ice protection systems (WIPS). New components shall significantly improve aircraft safety and reduce energy consumption compared to today´s systems. Please visit our website

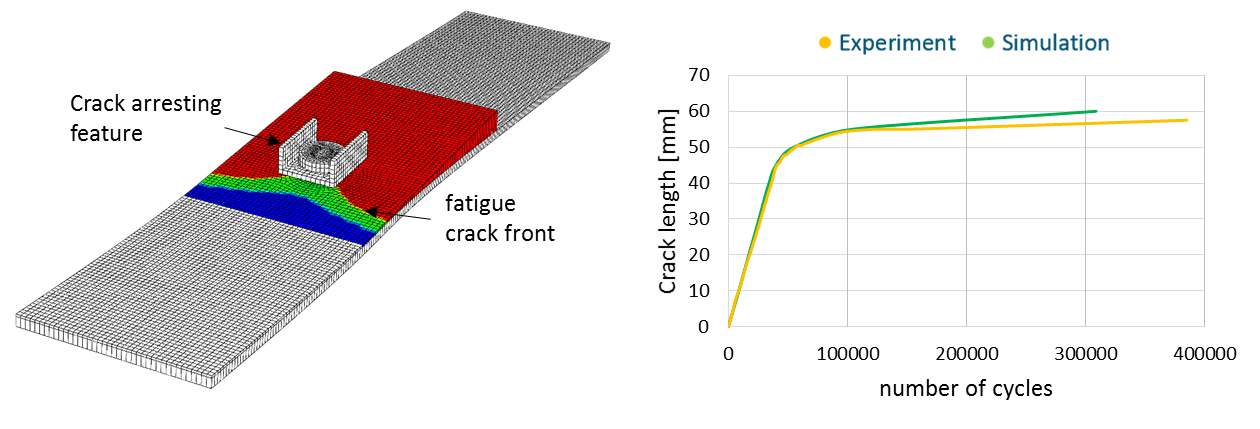

BOPACS “Boltless Assembly Of Primary Aerospace Composite Structures“, an EU FP7 project, aims to reduce weight and cost of aerospace structures through the design of damage tolerant adhesive joints. Based on a road map to certification that is being developed within the project, the research focuses on features that arrest crack growth and disbond extension within the adhesive bondline considering high-cycle fatigue loading.

BOPACS “Boltless Assembly Of Primary Aerospace Composite Structures“, an EU FP7 project, aims to reduce weight and cost of aerospace structures through the design of damage tolerant adhesive joints. Based on a road map to certification that is being developed within the project, the research focuses on features that arrest crack growth and disbond extension within the adhesive bondline considering high-cycle fatigue loading.

The myCopter project (2011-2014) aimed to pave the way for personal aerial transportation by investigating the enabling technology required to make Personal Aerial Vehicles (PAVs) a reality. To this end, models reproducing the handling dynamics for potential PAVs were designed and implemented on unmanned aerial vehicles and in motion simulators.

The myCopter project (2011-2014) aimed to pave the way for personal aerial transportation by investigating the enabling technology required to make Personal Aerial Vehicles (PAVs) a reality. To this end, models reproducing the handling dynamics for potential PAVs were designed and implemented on unmanned aerial vehicles and in motion simulators.

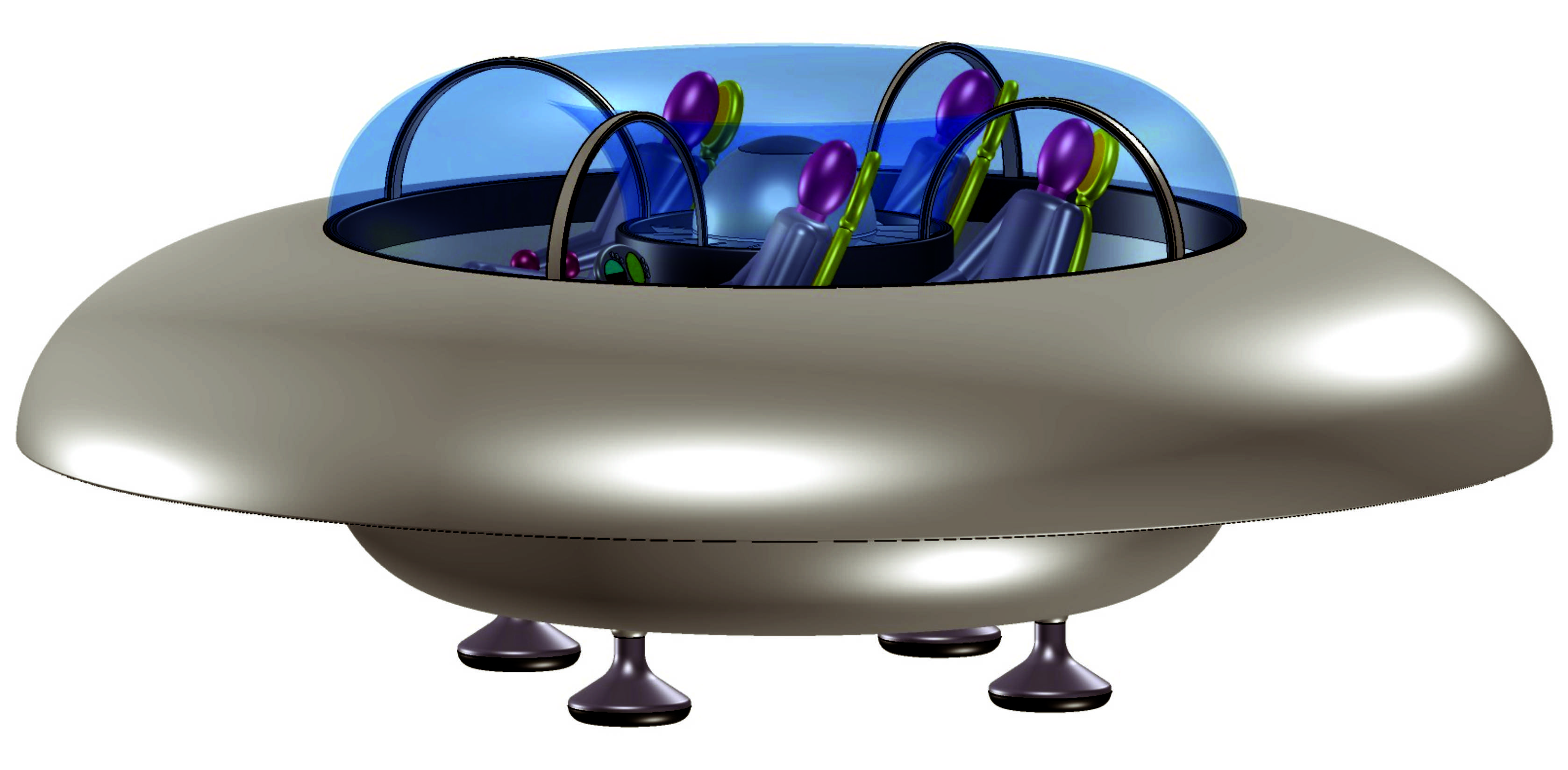

The principal objective of this project is the computational and experimental investigation of a novel concept of VTOL aircraft - the Anuloid – with respect to its flying qualities, structural feasibility, and aerodynamic characteristics. The Anuloid is conceived for transport missions in urban areas. The Anuloid has a toroidal shape and a turboshaft engine in its centre that drives a ducted rotor.

The principal objective of this project is the computational and experimental investigation of a novel concept of VTOL aircraft - the Anuloid – with respect to its flying qualities, structural feasibility, and aerodynamic characteristics. The Anuloid is conceived for transport missions in urban areas. The Anuloid has a toroidal shape and a turboshaft engine in its centre that drives a ducted rotor.

The RBF4AERO RBF-morphing based process for shape optimization and mode-superposition FSI has been effectively set for working with the open source tools SU2 and OpenFOAM®. Next commercial software to be linked are FINE™/Open with OpenLabs™ and FINE™/Turbo. Relating to icing simulation, all foreseen approaches have been tested and related applications have been successfully developed. As far as adjoint-morphing coupling is concerned, test cases of industrial interest have been accomplished in the respect of the envisaged computational techniques: Adjoint Preview and Adjoint Sculpting. Soon the RBF4AERO platform will be made available as a cloud-based solution supplied by an EU HPC center. Keep up-to-date on the RBF4AERO headway visiting our website:

The RBF4AERO RBF-morphing based process for shape optimization and mode-superposition FSI has been effectively set for working with the open source tools SU2 and OpenFOAM®. Next commercial software to be linked are FINE™/Open with OpenLabs™ and FINE™/Turbo. Relating to icing simulation, all foreseen approaches have been tested and related applications have been successfully developed. As far as adjoint-morphing coupling is concerned, test cases of industrial interest have been accomplished in the respect of the envisaged computational techniques: Adjoint Preview and Adjoint Sculpting. Soon the RBF4AERO platform will be made available as a cloud-based solution supplied by an EU HPC center. Keep up-to-date on the RBF4AERO headway visiting our website:

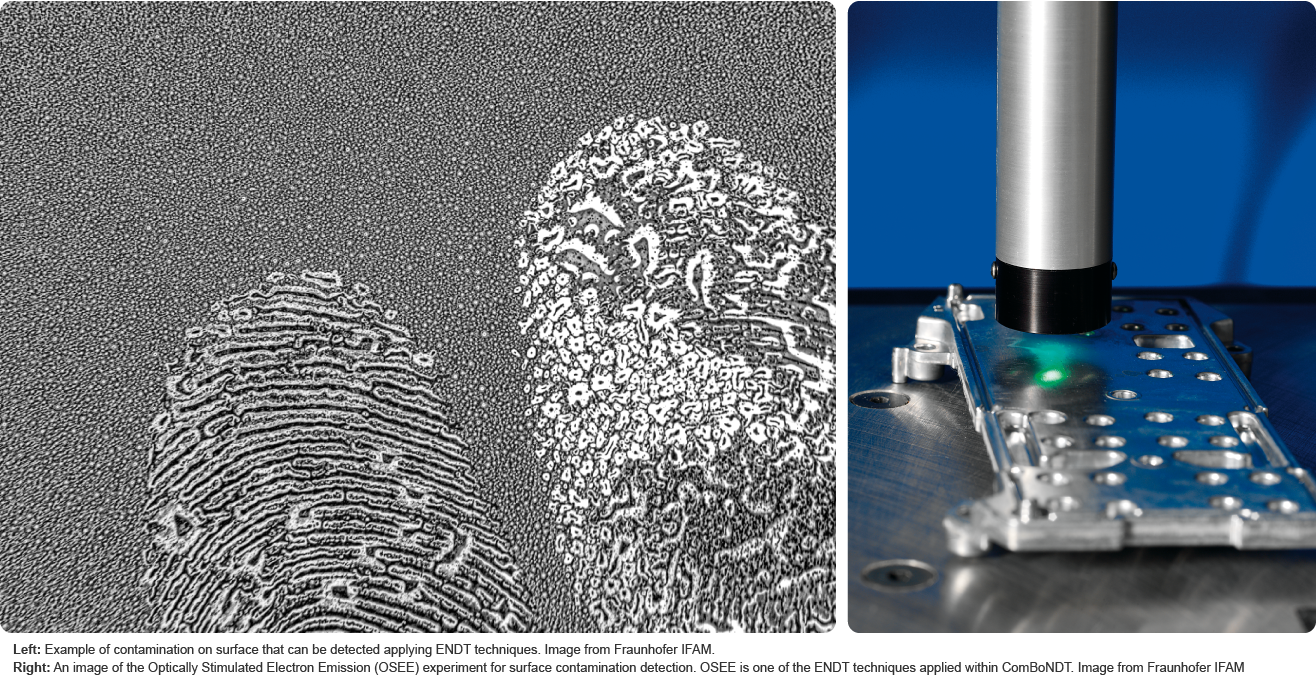

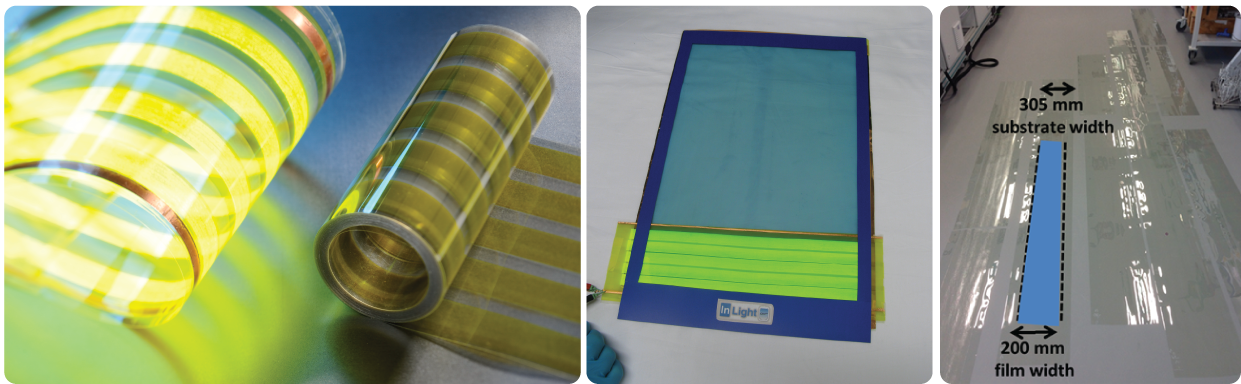

New non-destructive inspection technique for composite components!

New non-destructive inspection technique for composite components!

A droop nose morphing wingtip has been developed by the Institute of Composite Structures and Adaptive Systems of the DLR as part of the EU project NOVEMOR. The application was a regional jet from project partner Embraer, and wind tunnel tests at the University of Bristol showed the structure performing as desired under aerodynamic loads.

A droop nose morphing wingtip has been developed by the Institute of Composite Structures and Adaptive Systems of the DLR as part of the EU project NOVEMOR. The application was a regional jet from project partner Embraer, and wind tunnel tests at the University of Bristol showed the structure performing as desired under aerodynamic loads.